Overview

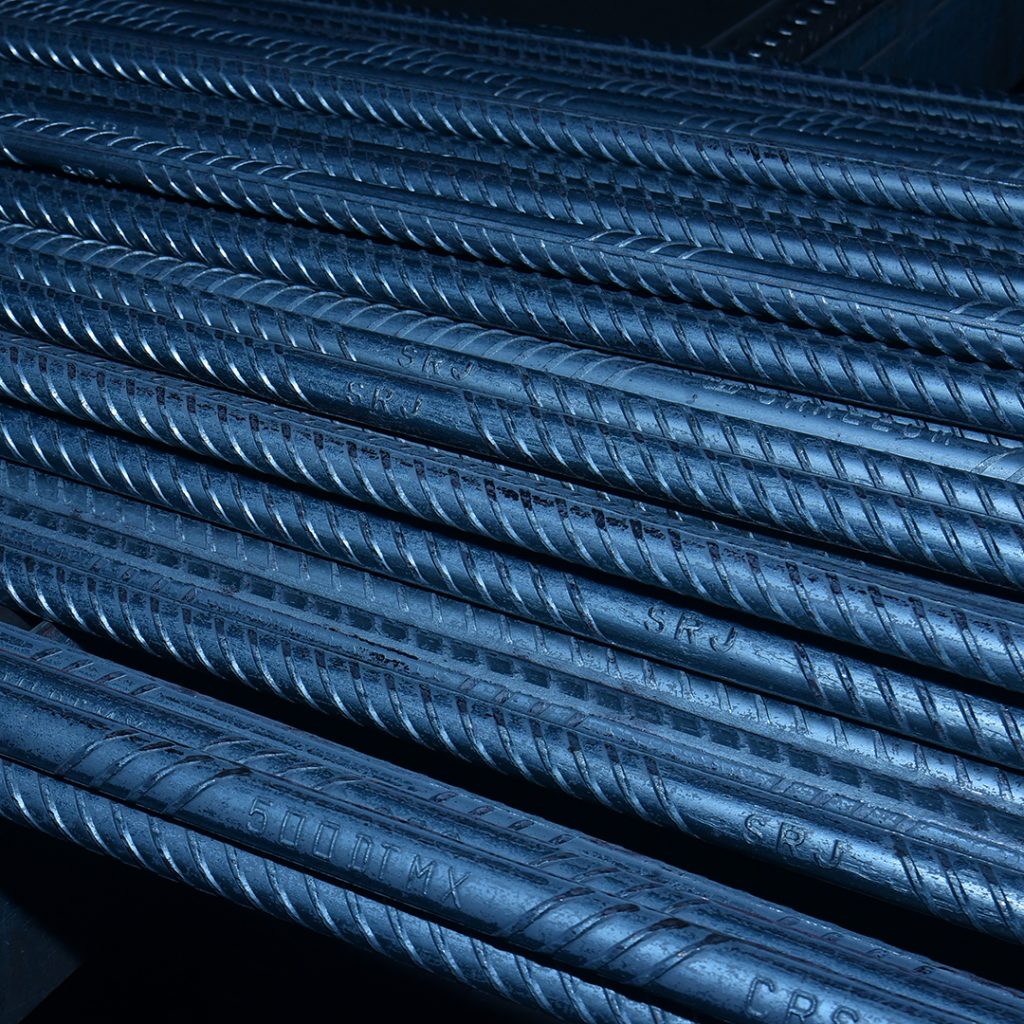

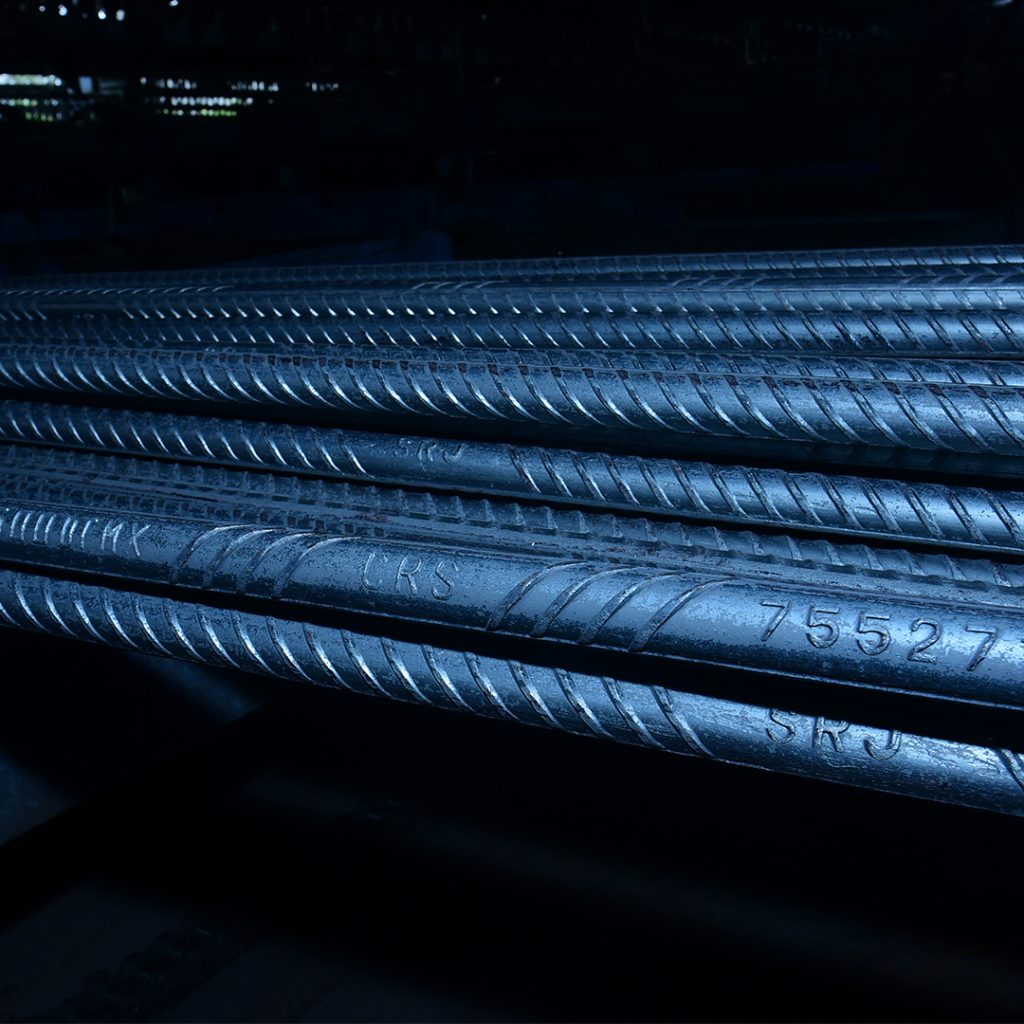

SRJ 500 grade rebars are easily the superior option to conventional bars, offering not only higher strength, elongation, durability, and concrete adhesiveness, but also enhanced savings in steel, one of the country’s most precious resources. These are manufactured using the patented ‘Thermex’ process.

Powerful Solutions and World Class Service

We envision a future that puts us in the lead role in this dynamic Maharashtra steel industry and amongst the top key steel players. At SRJ Steel, we not only dream big, but achieve bigger. We are always adding more value to our products and services through innovations. The company plans to expand its production capacity Very Soon.

We at SRJ Steel have a firm grip on the present and a sharp eye on the future. Our foremost priority is pioneering the products market with best quality and price offerings, along with attainment of highest level of customer satisfaction. With this vision about to become a reality, we are steadily marching towards an even brighter future. The values and culture at SRJ Steel will stand tall to ensure a thriving working environment that is safe, healthy and clean. We are a company that cares – about its people, its environment and its community.

To be one of India’s most trusted manufacturers of steel bars by utilizing, the latest techniques and advances from around the world.

SRJ THERMEX 500 TMT

Overview:

Manufactured using the patented ‘Thermex’ process, SRJ 500 grade rebars are easily the superior option to conventional bars, offering not only higher strength, elongation, durability and concrete adhesiveness, but also enhanced savings in steel, one of the country’s most precious resources.

Product Range :

We produce & supply TMT bars

- Size – Diameter 8 mm up to 32mm

- Grade – Fe 415, Fe 500, Fe 550, Fe 500 D and Fe 500 CRS as per IS 1786

- Product Embossing – Our product is embossed with ISI mark and our brand name at 1 meter intervals along its length

Features :

WHAT MAKES SRJ THERMEX TMT THE MOST TRUSTED BRAND?

- Higher elongation – we assure min. 15% elongation.

- Grade – Fe 415, Fe 500, Fe 550 and Fe 500 D as per IS 1786.

- Better corrosion resistance – no corrosion or rusting even after a long duration.

- Thermal stability – it can be used even at high temperatures till 600° C without any drop in strength.

- Excellent straightness – perfect straightness is ensured.

- Higher weldability – excellent weldability achieved because of optimum chemical composition.

- Earthquake resistance – higher elongation ensures greater safety.

- Prominent ribs CNC rib cutting ensures very prominent ribs.

- Higher ductility – excellent bendability.

WEIGHT TOLERANCE

| Size (Dia) of bar (mm) | Area(mm2) of bar Standard weight As per IS 1786 | Section wt.(Kg/m) as per IS 1786 | Length of Bar (mtr) | Weight of 1 Bar of SRJ (Kg/m) | No.of Bar in 1 Bundle | SRJ Bundle (Wt. in Kg) | No.of Bar in 1 MT | No.of Bundle in 1 MT | ||||

| Lower | Standard | Higher | Lower | Higher | Lower | Higher | ||||||

| 6 | 28.30 | 0.206 | 0.222 | 0.238 | 12.0 | 2.5 | 2.7 | 23 | 75.9 | 83.9 | 299 | 13 |

| 8 | 50.30 | 0.367 | 0.395 | 0.423 | 12.0 | 4.5 | 4.9 | 17 | 77.0 | 80.0 | 221 | 13 |

| 10 | 78.60 | 0.574 | 0.617 | 0.660 | 12.0 | 7.0 | 7.7 | 11 | 77.0 | 80.0 | 143 | 13 |

| 12 | 113.10 | 0.844 | 0.888 | 0.932 | 12.0 | 10.3 | 10.9 | 8 | 82.0 | 84.0 | 104 | 13 |

| 16 | 201.20 | 1.501 | 1.580 | 1.659 | 12.0 | 18.3 | 19.5 | 4 | 73.0 | 75.0 | 56 | 14 |

| 20 | 314.30 | 2.396 | 2.470 | 2.544 | 12.0 | 29.0 | 30.2 | 3 | 87.0 | 90.0 | 36 | 12 |

| 25 | 491.10 | 3.734 | 3.850 | 3.966 | 12.0 | 45.3 | 47.1 | 2 | 45.3 | 46.5 | 22 | 22 |

| 28 | 615.80 | 4.685 | 4.830 | 4.975 | 12.0 | 56.8 | 59.0 | 1 | 56.6 | 58.0 | 17 | 17 |

| 32 | 804.60 | 6.121 | 6.310 | 6.499 | 12.0 | 74.0 | 76.5 | 1 | 74.0 | 76.3 | 13 | 13 |

CHEMICAL PROPERTIES

| Element (%max) | Indian Standard (1786:2008) | SRJ Chemical | ||||||||

| FE 500 | FE 500D | 500D CRS | FE 550 | FE 550D | FE 500 | FE 500D | 550 | 550D | 500D CRS | |

| Carbon, Max | 0.30 | 0.25 | 0.15 | 0.30 | 0.25 | 0.22 | 0.20 | 0.25 | 0.20 | 0.11 |

| Sulphur, Max | 0.055 | 0.040 | 0.040 | 0.055 | 0.040 | 0.045 | 0.035 | 0.042 | 0.035 | 0.035 |

| Phosphorus, Max | 0.055 | 0.040 | 0.120 | 0.050 | 0.040 | 0.050 | 0.035 | 0.045 | 0.035 | 0.070 |

| S & P, Max | 0.105 | 0.075 | – | 0.100 | 0.075 | 0.090 | 0.070 | 0.085 | 0.070 | – |

| CR,CU, NI, MO,P min | 0.400 | 0.480-0.530 | ||||||||

MECHANICAL PROPERTIES

| Properties | Indian Standard (1786:2008) | SRJ Mechanical | ||||||||

| FE 500 | FE 500D | 500D CRS | FE 550 | FE 550D | FE 500 | FE 500D | 550 | 550D | 500D CRS | |

| Yield Strenght 0.2%Proof Strength (N/mm2)Min | 500 | 500 | 500 | 550 | 550 | 530 | 540 | 580 | 585 | 500 |

| UTS, Ultimate Tensile Strength (N/mm2)Min | 545 | 565 | 565 | 585 | 600 | 615 | 625 | 650 | 665 | 565 |

| % Elongation min | 12.0 | 16.0 | 16.0 | 10.0 | 14.5 | 16-20 | 18-22 | 16-20 | 18-22 | 16.0 |

| total Elongation % min | nil | 5.0 | 5.0 | nil | 5 | nil | 7.0 | nil | 8 | 5.0 |

| UTS/YS Ratio | 1.08 | 1.10 | 1.10 | 1.06 | 1.08 | 1.16 | 1.15 | 1.12 | 1.14 | 1.10 |